Torotic set out to solve a common problem in children’s coding education: students often write code but never see it work in the real world. The goal was to create a robot that was affordable, modular, and ready-to-use—giving kids the ability to upload code and immediately see it come to life.

PrototyperLab supported Torotic through the whole cycle: concept development, engineering, prototyping, and production. The result is a versatile learning robot built for hands-on education.

Key Requirements

To meet the goals of real-world coding education for kids, Torotic needed specific technical and production capabilities from day one.

- Affordable, low-volume production for early testing

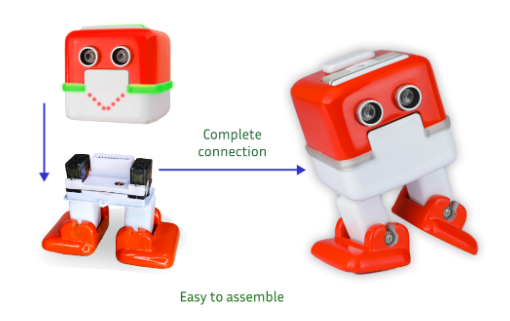

- Pre-assembled robot core with plug-and-play modules

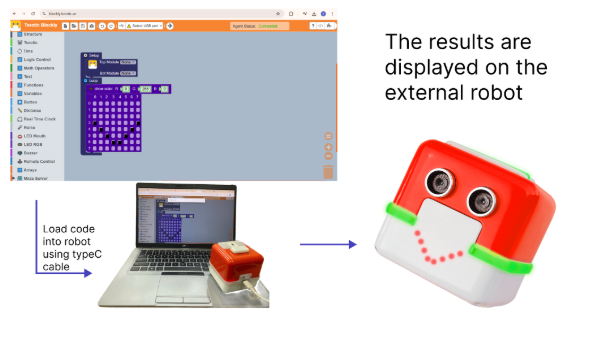

- Real-world execution of code written in a block-based editor

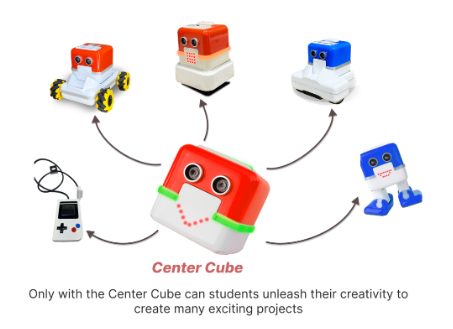

- Modular platform for gradual expansion

Features

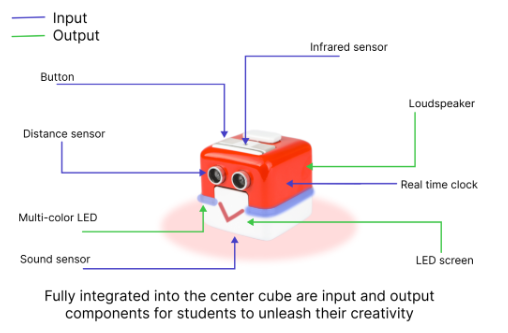

These are the core components and systems that made the Torotic robot functional, expandable, and ready for real-time student interaction.

- CenterCube Core Unit: Fully assembled hub for modular attachment

- Custom Blockly-Based Interface: Visual programming tool adapted for hardware integration

- Input Sensors: Sound sensor, distance sensor, button, real-time clock, IR receiver

- Output Components: LED screen, multicolor LED, speaker

Development Process

Torotic completed the project in 690 engineering hours using PrototyperLab’s structured prototyping workflow. Each step focused on building a usable, testable product without unnecessary delays or overspending.

The team handled all development phases under one roof:

- Hardware System Design: Planned and built the core structure, motion system, and modular shell to support quick assembly and expansion.

- Circuit Development: Designed, tested, and integrated electronics to support plug-and-play sensors and output components.

- Firmware Programming: Created the internal logic to control robot functions and enable communication between hardware modules.

- 3D-Printed Enclosures: Produced robust, lightweight shells for the core unit and add-ons to keep costs low and turnaround fast.

- Custom Blockly Integration: Adapted the visual programming tool for direct USB upload and real-time hardware interaction.

- STEM Curriculum Creation: Developed a 150-hour instructional program, including lectures, exercises, and hands-on activities to support educational use.

Prototyping and Development

Instead of navigating multiple vendors, slow timelines, and hidden costs, Torotic worked under one roof with a dedicated engineering team.

Every phase was handled quickly and transparently, from initial concept sketches to electronics design, 3D-printed enclosures, and custom code integrations.

R&D Breakdown

| Phase | Description | Hours |

| Hardware System Design | Circuits, shell, motion system, and modular structure | 360 hrs |

| Programming System | Custom visual coding platform, interface UX | 70 hrs |

| Courseware Development | 150-hour curriculum: lectures, videos, exercises | 260 hrs |

Challenges Addressed

Throughout development, several technical and usability issues were identified and resolved to make the product practical and classroom-ready.

- Assembly Complexity: Reduced with CenterCube’s pre-built core

- Code-to-Real Gap: Solved by real-time USB upload and hardware response

- High Cost of Flexibility: Avoided with modular design

- Limited Engagement: Overcome by bundling sensors and outputs for creative projects

Outcome

The robot is now in use for STEM education in classrooms and at home. With a 150-hour curriculum and support for dozens of projects, the product delivers real-world coding experience at an accessible price.

Why Torotic Chose PrototyperLab

For a robotics startup with big ideas and a lean budget, PrototyperLab delivered exactly what was needed:

- 7-day rapid prototyping to accelerate development

- 20-unit minimum production to validate demand

- Transparent $25/hour engineering pricing for predictable costs

- US contracts with Vietnam-based production for cost-efficiency and legal protection

- Hands-on expertise in consumer electronics and education tech

As one Torotic founder put it: “We wanted a functional, expandable robot that didn’t blow our budget. PrototyperLab helped us make it real—fast.”

If you’ve got a product idea like Torotic, and you need to test the market without risking $10K upfront, PrototyperLab can help.