Bringing a physical product idea to life is exciting—but asking how much does a prototype cost? often leads to a confusing range of answers. Some say $500. Others quote $15,000 or more.

For startup founders, e-commerce sellers, and first-time inventors, that lack of clarity is a dealbreaker.

This article breaks down the real costs of prototyping a physical product—so founders can make smart decisions without overspending or guessing blindly.

Why Prototype Costs Vary So Widely

There’s no single price tag for prototyping because every product is different. A Bluetooth-connected IoT device will cost more than a plastic kitchen accessory. But most prototypes share the same categories of costs:

Engineering and Design Time

This is usually charged by the hour. Engineers need to convert their idea or sketch into a 3D CAD model, run simulations, and finalize designs. For simple products, this may take 10–20 hours. More complex devices might require 40–100+ hours.

- Typical rate: $25/hour–$200/hour

- Startup-friendly range: $500–$2,500 (based on $25–$75/hr and product complexity)

Materials and Components

This includes the raw material used to produce the prototype—plastic, metal, silicone, electronics, etc. Prices vary based on quality, function, and quantity required for testing.

Examples:

- PLA plastic for 3D printing: low cost

- CNC-machined aluminum: higher cost

- Off-the-shelf electronic modules: variable

Estimated cost: $50–$800 per prototype unit

Prototyping Method

Different methods impact pricing:

- 3D printing – Fast and cheap for most designs

- CNC machining – Ideal for functional and durable parts

- Vacuum casting or silicone molding – Useful for appearance models or short-run testing

- PCB prototyping – Required for electronics; adds time and cost

Typical cost range: $150–$2,000+ depending on method and part count

Prototype Cost Breakdown by Complexity

| Product Type | Estimated Total Prototype Cost |

| Simple plastic item (no electronics) | $600–$1,500 |

| Gadget with moving parts | $1,500–$3,000 |

| Consumer electronics prototype | $3,000–$7,500 |

| Complex multi-part device | $7,500–$15,000+ |

Pro tip: Start with the minimum viable prototype to validate core functionality. Add features later.

Hidden Costs Founders Often Miss

While pricing a prototype, it’s easy to forget the “invisible” costs that hit later:

- Design revisions – Every change adds hours and rework

- Testing and validation – You may need more than one version

- Compliance research – Especially for electronics, toys, or products for kids

- Shipping and logistics – International shipping of parts or finished prototypes

These extras can tack on an additional 15–40% to your prototyping budget if not factored in early.

What About Small Batch Production?

Once the prototype is finalized, most founders want to produce a short run to validate demand. This is where traditional factories often kill momentum by requiring 500+ unit minimums.

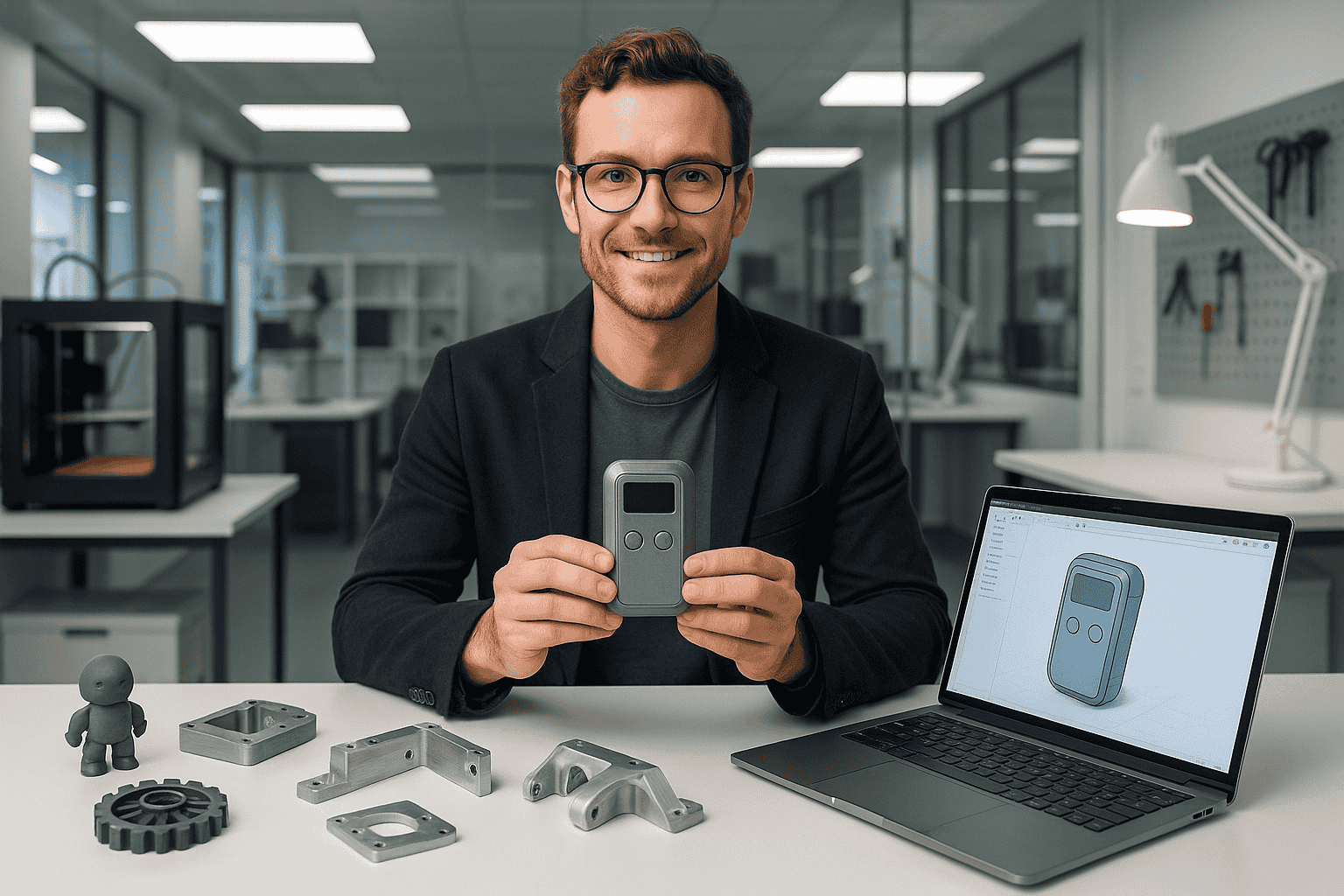

Startup-focused services like PrototyperLab offer small batch production starting at just 20 units, giving founders the flexibility to:

- Launch a Kickstarter campaign

- Sell on Amazon or Shopify

- Test product-market fit

- Gather customer reviews before scaling

Small batch manufacturing cost: $15–$80 per unit depending on materials, complexity, and volume

4 Ways to Keep Prototype Costs Low (Without Cutting Corners)

Founders don’t need to throw $10K at a prototype just to test a product idea. Here’s how to reduce cost without compromising quality:

1. Work with a Team That Offers Transparent Pricing

Choose firms that publish rates (like $25/hour) and break down estimates clearly. Avoid vague ranges or agencies that won’t commit until deep into a contract.

2. Skip Fancy Finishes in Early Versions

Use PLA instead of injection-grade ABS. Skip matte coatings or die-cast parts. Go functional first.

3. Combine Design and Engineering

A single firm that handles CAD, prototyping, and small batch production will move faster and avoid markups between steps.

4. Focus on Core Features

Don’t prototype version 5.0 when version 1.0 is enough to test demand. Strip to MVP form and iterate.

Freelancers vs. Full-Service Prototyping Teams

| Freelancers | Full-Service Prototyping Team |

| Lower hourly rates | End-to-end process, fewer gaps |

| Often need project management by founder | Streamlined workflow |

| Risk of missed timelines or design errors | Legal protection & reliability |

| May lack manufacturing insight | Prototype designed with production in mind |

Bottom line: Freelancers can be cheap, but they’re not always lean.

Prototype Costs Are an Investment—But They Shouldn’t Be a Gamble

Smart founders treat prototype development as a strategic investment, not a blank check. You don’t need to max out your budget to get something testable and market-ready.

What you need is cost visibility, a trusted team, and the flexibility to start small.

If you’re serious about launching a physical product and want a clear cost breakdown with no hidden fees, PrototyperLab offers:

- 7-Day Prototyping

- $25/hour Transparent Engineering Pricing

- Small Batch Production (as low as 20 units)

- US-based Contracts, Vietnam-based Affordability

Get a Transparent Prototype Quote

FAQs: Cost of a Prototype

What is the average cost to build a prototype?

The average cost to build a prototype ranges from $600 to $7,500, depending on complexity, materials, and method used. Simple items may cost under $1,000, while complex electronics can exceed $10,000.

What’s included in prototype development costs?

Prototype costs typically include engineering/design time, materials, the prototyping method (like 3D printing or CNC), and any testing or iteration. Some services also include compliance research and small batch production estimates.

Can I prototype a product for under $1,000?

Yes, many founders can build a basic, functional prototype for under $1,000 using 3D printing and streamlined design, especially when working with a startup-friendly team offering transparent hourly pricing.

What’s the cheapest way to prototype a product?

The most affordable prototyping method is usually 3D printing, especially for simple designs. Partnering with a service that offers flat hourly engineering rates and small batch options keeps overall costs lower.

How many units do I need to manufacture after prototyping?

Startup-focused production services often offer low minimums—starting at just 20 units—making it easy to test demand before scaling to mass production.