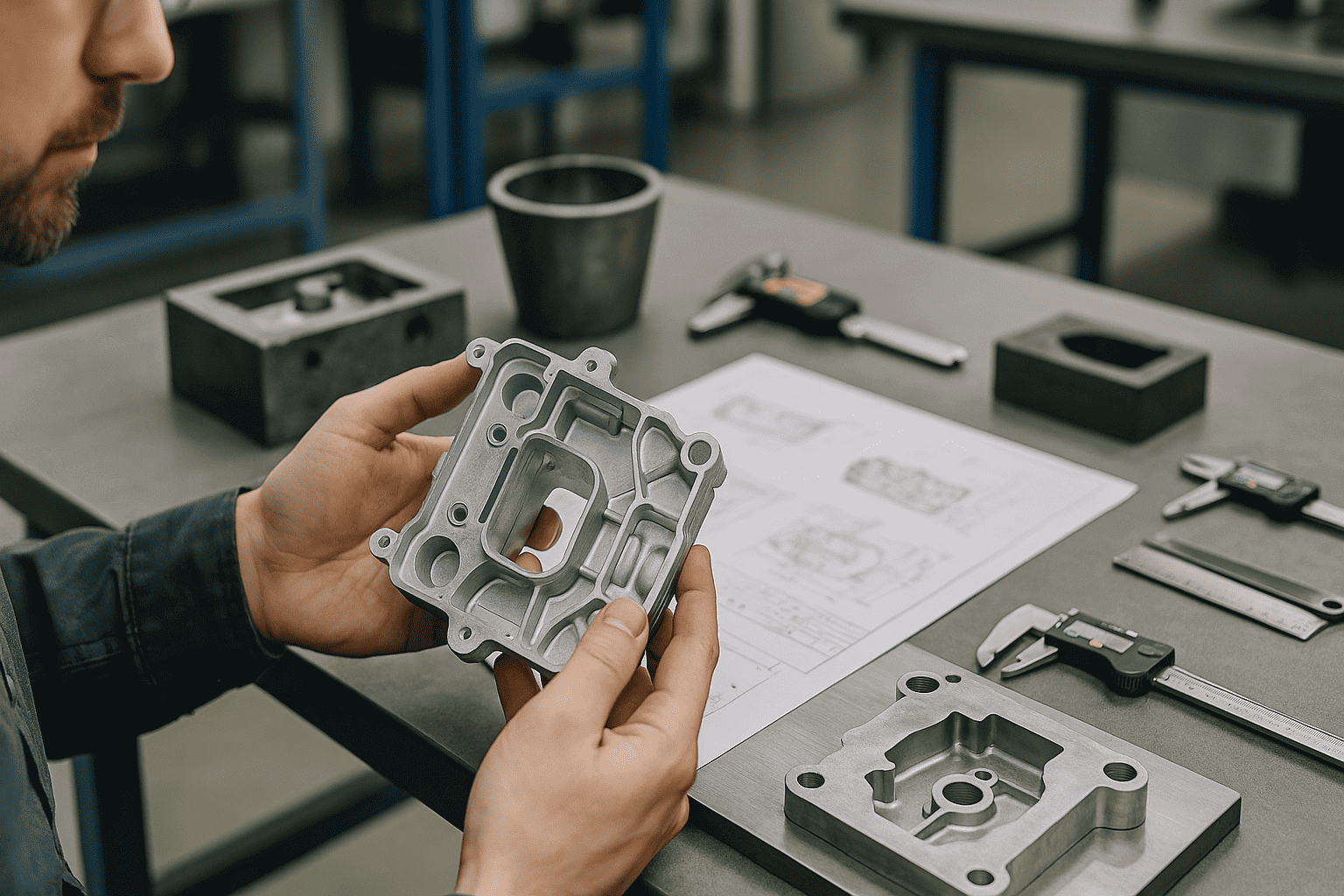

Startups working with metal face a common headache: CNC machining is too expensive for small runs, and 3D printing doesn’t offer the strength or surface quality needed for real-world testing.

If your product needs to be functional, polished, and production-ready—without producing 500+ units—traditional paths fall short.

That’s where pressure die casting enters the picture.

Originally seen as a mass production method, pressure die casting is now being adapted for low-volume, complex prototypes—perfect for bootstrapped founders who need 20–100 high-quality metal parts without breaking their budget.

What Is Pressure Die Casting?

Pressure die casting is a manufacturing process that injects molten metal (typically aluminum, zinc, or magnesium) into a custom steel mold (called a die) under high pressure. This results in parts that are:

- Highly repeatable

- Dimensionally accurate

- Smooth in surface finish

- Structurally strong

Because the mold is reusable and precise, the process is ideal for producing functional parts that look and behave like final production units.

Key advantages:

- Excellent for parts with thin walls and complex geometry

- Tighter tolerances than sand casting or manual methods

- Faster than CNC when part count exceeds ~10 units

Why It’s a Game-Changer for Startups

For startups building hardware products—smart gadgets, enclosures, brackets, hinges—pressure die casting offers several big wins:

- Functional quality in low volumes: Unlike 3D prints, die cast metal parts hold up in real-world testing.

- Smooth, investor-ready aesthetics: No post-processing needed for a clean, professional finish.

- Cost efficiency after tooling: Once the mold is created, each unit becomes significantly cheaper than CNC.

- Repeatability: Each part is identical, essential for early customer trials and quality validation.

Startups need to validate fast. Pressure die casting lets them do that without sacrificing quality or overspending.

Can Pressure Die Casting Be Low-Volume? Yes—Here’s How

Most founders assume die casting requires massive order volumes.

In reality, low-volume pressure die casting is not only possible—it’s increasingly common for pre-launch validation.

How?

- Aluminum or soft steel molds can be used for just 20–100 parts.

- Tooling is simplified, avoiding the need for hardened production dies.

- Lead times are faster—PrototyperLab can ship production samples in just 30 days.

Use cases include:

- A startup launching on Kickstarter with 50 metal enclosures.

- An e-commerce founder needing 25 units to test on Amazon.

- A robotics company validating a design before committing to mass tooling.

No 500-piece commitment. Just enough to launch smart.

Pressure Die Casting vs. Other Metal Prototyping Methods

Here’s how pressure die casting compares with CNC machining and metal 3D printing:

| Method | Best For | Limitations |

| CNC Machining | One-off precision parts | Expensive and time-consuming for complex parts |

| 3D Metal Printing | Quick turnaround on simple designs | Limited strength, surface quality, and cost per unit |

| Pressure Die Casting | Small batches of complex metal parts | Requires upfront tooling investment |

If you need complex geometry, tight tolerances, and 20–100 parts, die casting outperforms both alternatives.

How Much Does Low-Volume Die Casting Cost?

Tooling is the primary cost driver—but for low-volume runs, this can be optimized:

- Soft aluminum molds: ~70% cheaper than hardened production dies

- Total cost per unit drops dramatically after 10–15 parts

- Typical startup setup: $1,500–3,500 for tooling, $5–15 per part (depending on size and complexity)

Realistic project budget:

- $2,000–4,500 for 25–50 parts, including tooling and part cost

- Far more affordable than machining the same number of complex parts

When done right, pressure die casting is both lean and scalable.

Real Startup Use Cases

Case Study 1: A Wearable Tech Startup

- Needed 40 aluminum casings with internal bosses and a snap-fit design

- CNC quotes: $125 per unit

- Pressure die casting: $9.50 per unit (after tooling)

- Used units for investor demos and Kickstarter rewards

Case Study 2: Modular Robotics Kit

- Required 50 zinc brackets with thin arms and tight tolerances

- CNC could not replicate the thin features affordably

- Die casting handled it with no issue—parts tested well, earned 5-star reviews

These founders didn’t wait to “go big.” They got to market fast, validated demand, and earned the right to scale.

Pressure Die Casting at PrototyperLab

PrototyperLab helps bootstrapped hardware founders get complex metal parts into their hands—fast.

Here’s what makes the service unique:

- 7-Day Prototyping: Quickly test form, fit, and function before tooling

- Low-Volume Production: Order just 20–100 parts without factory headaches

- Transparent Pricing: $25/hour engineering rate, clear material costs

- US-Based Legal Contracts: No international payment issues or legal gray zones

- Vietnam Manufacturing: World-class output at competitive cost

From CAD to customs, it’s a streamlined pipeline optimized for startups—not big factories.

Is Pressure Die Casting Right for Your Prototype?

Choose die casting if you:

- Need durable, repeatable metal parts (not plastic)

- Have complex geometry that CNC can’t cheaply handle

- Want to produce 20–100 parts for testing or launch

- Value production-quality results without committing to mass production

It may not be right if:

- You need just one or two parts (use CNC or 3D printing instead)

- Your timeline doesn’t allow for tooling (use additive prototyping)

Still unsure? PrototyperLab’s engineers can review your CAD files and advise on the best path forward.

Build Better, Test Faster

For startups working on metal products, pressure die casting has become a powerful tool for low-volume validation. It delivers the polish and precision of production without forcing founders into risky, oversized commitments.

If your part needs to be strong, sleek, and repeatable—this is the path worth considering.

Need help getting started? PrototyperLab can prototype your part in 7 days and produce as few as 20 metal units—all with U.S. contract protection and transparent pricing.